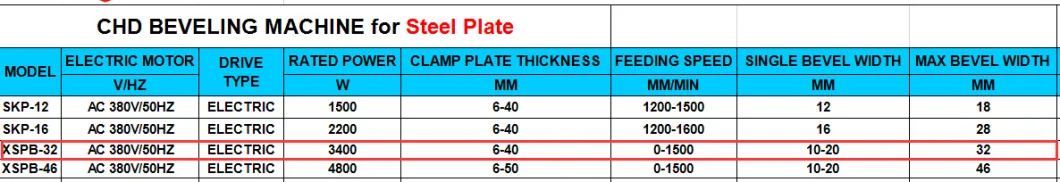

Monthly Deals High Quiality Milling Type Plate Edge Grooving Machine

Product picture Application The milling type beveling machine will automatic move beveling, reduced the cost and labor i;

Basic Info.

| Model NO. | XSPB-32 |

| Standard Blades | 10 Degree to 60 Degree |

| Beveling Machine Color | Blue/Yellow or Customized |

| Motor Speed | 1050r/Min |

| Feed Speed | 0-1500mm/Min |

| ODM | Yes |

| Application | Petroleum, Chemical Industry, Electric Power etc. |

| OEM | Yes |

| Beveling Machine Usage | for Metal Plate Beveling |

| Rated Frequency | 50Hz/60Hz |

| Voltage | AC380V |

| Clamp Plate Thicknes | 6-40mm |

| Rated Power | 3.4kw |

| Product Name | Electric Plate Beveling Machine |

| Driven Type | Electric |

| Model | Xspb-32 |

| Transport Package | Metal Box & Non Fumigation Wooden Box |

| Specification | As technology specification |

| Trademark | CHD |

| Origin | Shanghai China |

| HS Code | 8456909 |

| Production Capacity | 10000 Set/Year |

Product Description

Product picture

Application

The milling type beveling machine will automatic move beveling, reduced the cost and labor intensity, it adopts cooling milling process, the process surface is not oxidized after milling or beveling. The high finish of groove can meet with the requirements of the welding industry, without deburring treatment can bu used immediately. And this product is pollution-free and simple operation.

Function

The installation is simple and convenient, groove assignment is fast. It is applicable to various kinds of materials processing, and available to a wide range of pipe diameter. As it adopts mechanical cutting groove method, it can keep the mechanical properties of material quality well. And it also could do 10degree to 60degree groove angle to the plate. Thus, it could meet with all the requirements for butt welding.

Features

1. Automatical self-walking design, degree and speed adjustable2. No deformation, not effect steel plate raw material3. Perfect effeciency4. Milling knife run high speed, smooth highly5. Simple operation, worker can operate some machines meanwhile6. Suitable to carbon steel, stainless, aluminum alloy steel, etc.7. High beveling speed and labour saving8. Bevel angle: 10degree to 60degreeAfter Beveling:

Steel scrap:

Technology specification

FAQ:

1) Are you Manuacturer? RE:Yes.2) How to choose a right model?RE: Please let us know more details about the pipe, such as the I.D, O.D, the materials of the pipe, the environment of the site and the requirement of the end face, etc. These will help us to choose the right model for you immediately.3) Do you have another choice about the driven?RE: Of course. We have many choice for you to choose, such as electric, pneumatic, hydraulic, NC, etc.4) Which type of beveling machine do you have?RE: Internal expansion type, external installed type, plate beveling machine, desktop precision pipe cutting machine.5) Do you support the special needs?RE: Yes, we have many engineers. We could design it according to your need.6) How about the payment term?RE: 30% advance payment and balance payment before the shipment by T/T.

7) How can we guarantee quality?

RE:Always a pre-production sample before mass production;

Always final Inspection before shipment.

8) Why should you buy from us not from other suppliers?

RE:1.more than 30 years produce and manage experience.

2.widely business range, one station service

3.many certificates approved company

4.professional technical team 5.good reputation in industry.

9) What services can we provide?

RE: 1.1year or 12months long warranty periods.

2. Many payment terms could be accepted, such as T/T, LC, West Union, Cash, etc.

3. Have showroom in Russia, India and Indonesia

4. English, Russia, Spanish, French, etc.WHY CHOOSE US?

CHD FACTORY

CHD OFFICE

CHD SALES TEAM

|

CHD was founded in 1989, is a High-Tech Enterprise which integrates R&D, Production, Sales and Service of cutting machine.

CHD, as one of the largest metal cutting machine manufacturers, headquartered in Shanghai, China. With 3 production bases, totally plant area of more than 53,000 square meters , respectively located in Shanghai, Chengdu and Wenzhou.

CHD focus on quality control, has passed many certification audits including ISO9000, SGS, CE, CCC, etc., was one of the world's largest manufacturer's partners of steel plate cutting equipment. CHD cutting machines have already been exported to more than 100 countries in the past 20 years.

Advantages of CHD

1. Large Production Capacity.16 R& D stuff, 120 Workers, 3 Production Bases,Plant of 53000 Square Meters. 10 Production Lines.

2. Full line of Products. Cutting Machine, Plasma Power, Welding Machine, Beveling Machine, Circular Cooling Water Tanks, Consumables.

3. Honesty. All parameters (cutting thickness & precision) are actual operation parameters without overstate.

4. Good after service, not one-off business.

5. One year guarantee. Free spare parts service on base of order amount. Engineer oversea service.

6. Adjustable Short Lead Time.

7. Quality been assurance. We are OEM supplier of one of world's largest cutting machine company. Most of our products have CE and CCC certificate.

Products on-site:

Our Certifications:

Our Exhibitions:

Welcome to contact us!

Best Regards!

You may also like

Send inquiry

Send now