Wf360d Edge Band Making Machine Woodmaster Edge Banding Corner Rounding Machine

Basic Info.

| Model NO. | WF360D |

| Panel Thinkness | 10-60mm |

| Min.length panel | No Limited |

| Min.width panel | 60mm |

| Manufacturing Principles | Glue Tank Overhead |

| Customized | Customized |

| Working Board Width | > = 60mm |

| Weight | 1200kg |

| Working Pressure | 0.6MPa |

| Voltage | 380V or 220V |

| Working Board Thickness | 10~60mm |

| Power | 7kw |

| Transport Package | Wooden Box |

| Specification | 3664x800x1600mm |

| Trademark | woodfung |

| Origin | China |

| HS Code | 8465940000 |

| Production Capacity | 100sets/Month |

Product Description

WF360D Edge Band Making Machine Woodmaster Edge Banding Corner Rounding Machine Edge Bander Woodfung WF360D corner rounding automatic edge banding woodworking machinery

WF360D automatic edge banding machine corner rounding Woodworking MachineryThis machine is specially designed and exclusive for foreign market by us,which is multifunction but favourable price.It is usedfor MDF,wooden board and shaving board.It can complete the processes of feeding workpiece,feeding coiled material,edging,endcutting,fine trimming,scraping and buffing.It can achieve the level as same as foreign machines and the price is favourable.It isespecially suitable for the factory producing board .

Main Material brand:DELTA Touch Screen/CHINT Electronic/DELTA PLC/solenoid valve AirTac/CSK guide/EASUN Cylinder

WF360D functions:Gluing → End Cutting → Rough Trimming→Fine Trimming →Corner Rounding→ Scraping → Buffing

WF360D woodworking edge banding machine full automatic CORNER ROUNDING edge bander Specifications:

| Model | WF360D |

| Motor power | 13.6KW |

| Panel width | ≥60mm |

| Panel thickness | 10~60mm |

| Edge band thickness | 0.4~3.0mm |

| Edge band width | 12~60mm |

| Feed speed | 0~13m/min |

| Working pressure | 0.7Mpa |

| size(LxWxH)cm | 5800×1000×1600mm |

| Weight | 2500KG |

Automatic edge bander for different board and different edge bander

PAINTFREE,LAMINATE,PRATICAL,MDF,SOLID PANELS SOFT VANEER,PVC,ACRYLIC,PMMA,ABS EDGE BANDERS

Automatic Edge bander application:

DELTA Touch Screen Operation Panel

Taiwan Delta PLC microcomputer control system adopts touch screen intelligent control, which is convenient, quick and easy to use

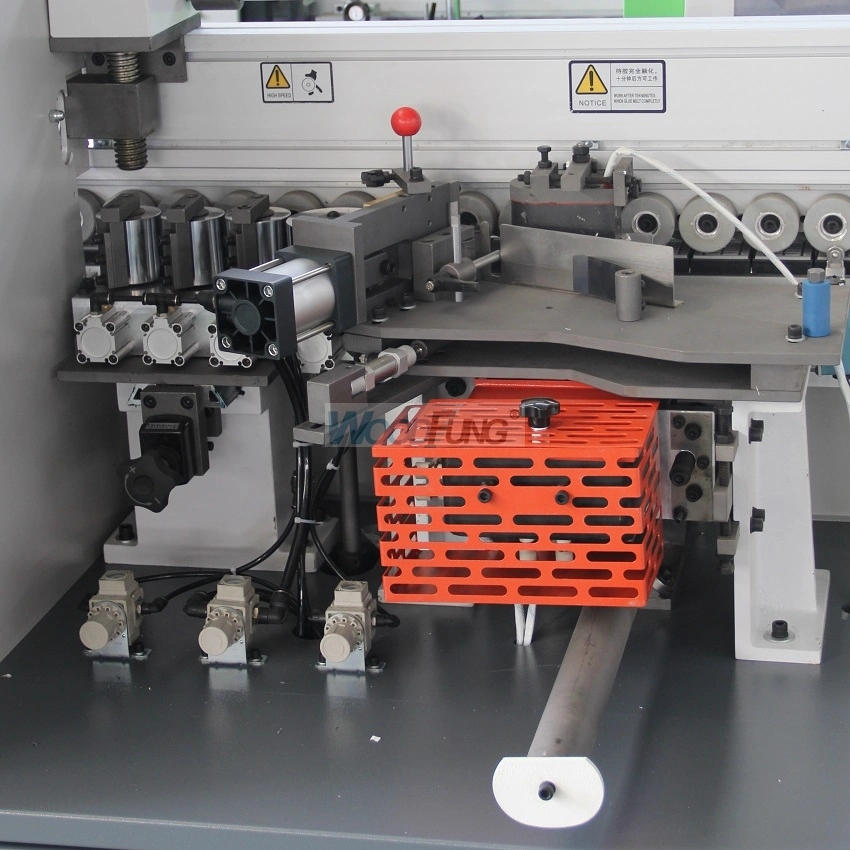

Gluing part

The glue pot is heated and glued, and the glue is coated with an imported technology structure to make the sheet and the edge banding evenly glued.

The edge band and the sheet are pressed tightly through the pressing wheel, and the adhesion is firm.

End Trimming

The front and rear aligning head is composed of the front aligning head and the rear aligning head. It moves through a linear CSK guide rail.

It adopts the structure of automatic tracking and high-frequency high-speed motor to make the cutting smooth

Rough Trimming

Rough trimming knife is used to leave a margin of 40-50 wire for fine trimming, and automatic die tracking and high-frequency high-speed motor are

used for rapid cutting.

Corner Rounding

The profiling tracking and rounding device can make the end surface of the plate smoother and look atmospheric

Related Products:

| Model | WF60E | WF360A | WF360B | WF360C | WF360YC | WF360YCC | WF360D |

| Motor power | 4KW | 7KW | 8.5KW | 8.5KW | 11KW | 19KW | 15KW |

| Panel width | ≥60mm | ≥60mm | ≥60mm | ≥60mm | ≥60mm | ≥60mm | ≥60mm |

| Panel thickness | 10~60mm | 10~60mm | 10~60mm | 10~60mm | 10~60mm | 10~60mm | 10~60mm |

| Edge band thickness | 0.4~3.0mm | 0.4~3.0mm | 0.4~3.0mm | 0.4~3.0mm | 0.4~3.0mm | 0.4~3.0mm | 0.4~3.0mm |

| Edge banding width | 12~65mm | 12~65mm | 12~65mm | 12~65mm | 12~65mm | 12~65mm | 12~65mm |

| speed | 0~13m/min | 0~13m/min | 0~13m/min | 0~13m/min | 0~13m/min | 0~13m/min | 0~13m/min |

| working pressure | 0.7Mpa | 0.7Mpa | 0.7Mpa | 0.7Mpa | 0.7Mpa | 0.7Mpa | 0.7Mpa |

| size(LxWxL)mm | 2740*850*1480 | 3700*930*1600 | 4080*930*160 | 4180*930*1600 | 5000*930*1600 | 5700*930*1600 | 5900*930*1600 |

| WF60E | gluing,trimming,scrapping and buffing,also with manual end cutting | ||||||

| WF360A | gluing,end cutting,fine trimming,scrapping and buffing | ||||||

| WF360B | gluing,end cutting,rough trimming,fine trimming,scrapping and buffing | ||||||

| WF360C | gluing,end cutting,fine trimming,scrapping,vertical grooving,horizontal grooving and buffing | ||||||

| WF360YC | pre-milling,gluing,end cutting,rough trimming,fine trimming,scrapping and buffing | ||||||

| WF360YCC | pre-milling,gluing,end cutting,fine trimming,scrapping,vertical grooving,horizontal grooving and buffing | ||||||

| WF360D | gluing,end cutting,rough trimming,fine trimming,corner rounding,scrapping and buffing | ||||||

FAQ:

Q1: What is the warranty for the machine?

For our wood machine, we have 18months warranty.

Q2:Can I choose the voltage?

Yes,we have 380V or 220V for choice for your country

Q3.What is your lead time after i pay?

Normally,we have stock for 380V,for the 220V customized,about 5days.

Q4:How long will i get the machine after i pay?

for small machine by air,about 7days,and for the big machine by sea.about 20~45days to your ports.

Q5:Is it OK to print my logo on the product?

Yes.Please inform us formally before our production and confirm the design firstly for the mass production.

Q6:It is my first time to purchase goods from china,how do i do?

Do not worry,Aucox has 10years export experience to all over the world,also has professional sales team,

we also have agent in Russia,Algeria,Pakistan,Peru,Vietnam,etc.

Q7:How to pack the machine?

we use wooden box to packge the machine to protect them to be safe

Q8.I do not know chinese,will the operation panel in english or spanish or other?

Yes,all our machine are with Chinese and English,If you want only English or Spanish or other,

we also can customize to you,but lead time will be a little longer.

Group&Stock&Delivery